Recently, the Civil Engineering Section 7 Project of the Fangcun – Baiyun Airport Intercity Railway was awarded the title of “Excellent Construction Project Department” in the 2024 Engineering Construction Evaluation by Guangzhou Metro Group Co., Ltd. for its outstanding construction performance. The project adopted high-quality tunnel boring machine (TBM) equipment independently developed by Guangzhou Sunward. Its stable and efficient performance has provided strong support for the smooth progress of the project. This achievement not only reflects the careful planning and unremitting efforts of the project department, but also demonstrates the technical strength and positive contribution of Guangzhou Sunward in the field of tunnel construction.

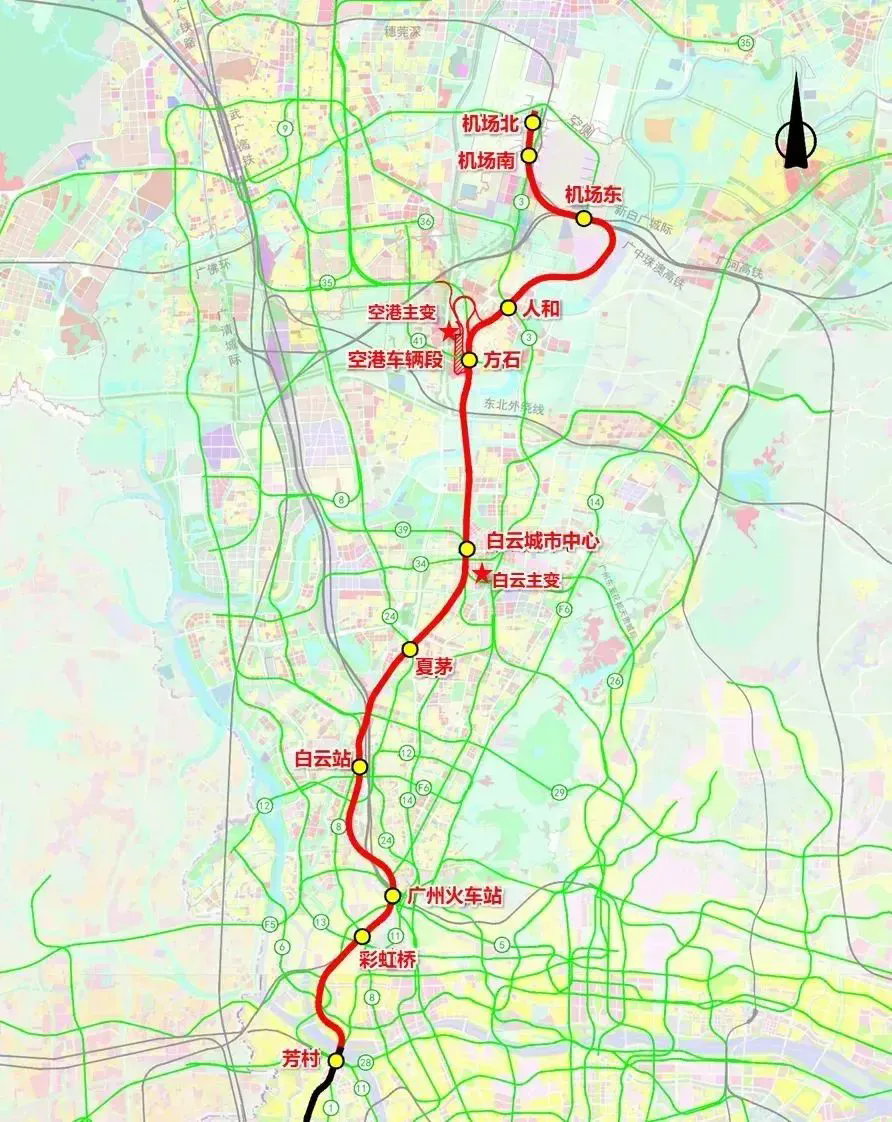

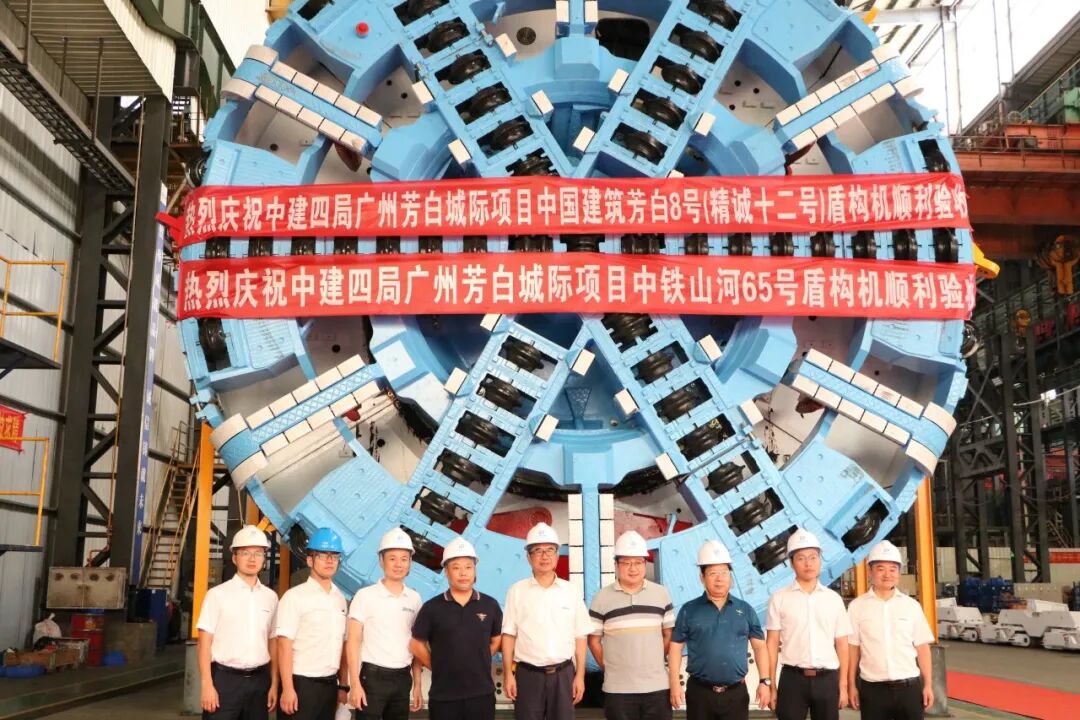

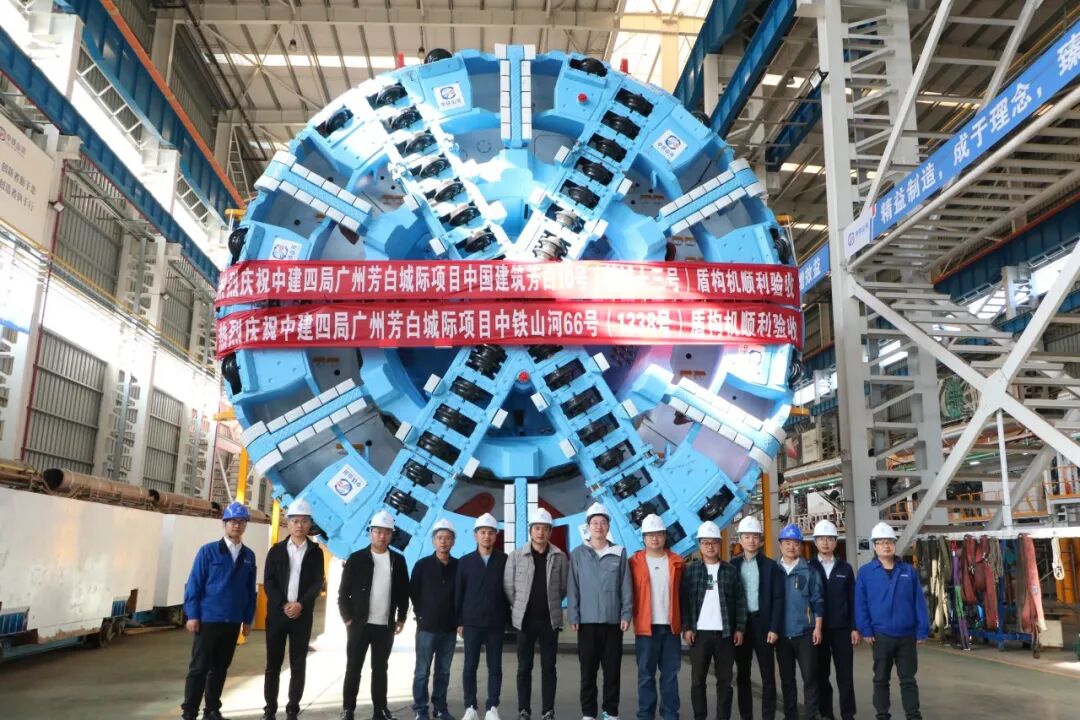

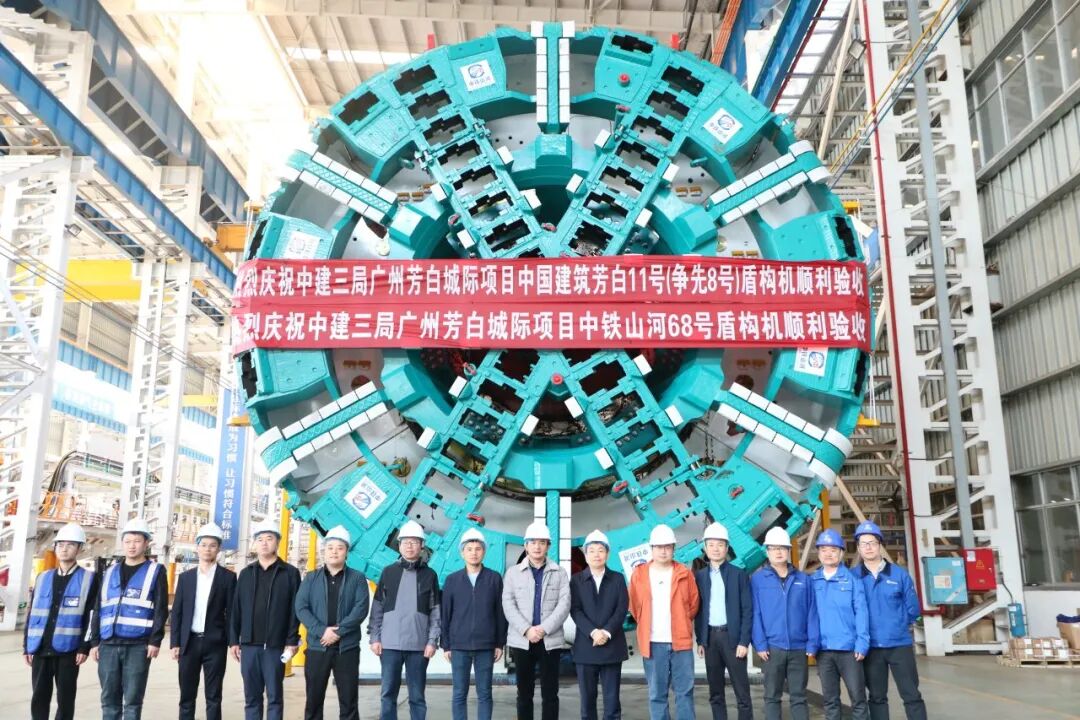

Guangzhou Fangcun – Baiyun Airport Intercity Railway (referred to as: Fangbai Intercity Project) is an important transportation link connecting Fangcun, Guangzhou and Baiyun International Airport. It is a key part of the intercity railway construction plan in the Greater Bay Area and bears the responsibility of regional interconnection. Guangzhou Sunward has specially customized four large-diameter intelligent TBMs for the Fangbai Intercity Project and applied them to the project construction.

The Fangbai Intercity Project faces complex engineering geological and hydrological conditions. The minimum curve radius of the tunnel is 350 meters, the single-line length is more than 1.5 kilometers, and there is an 800-meter uphill section with a slope of 34.53‰. The special vertical and horizontal curves of the line are the first of its kind in China. In response to the above engineering difficulties, the R & D team of Guangzhou Sunward carried out a series of targeted designs for the TBM. A shuttle – type shield structure with a large front and a small rear was adopted to reserve sufficient swing space for the tail shield during the turning process, effectively avoiding the occurrence of shield jamming. By shortening the length of the main engine and appropriately increasing the excavation diameter, it is ensured that the TBM can still maintain stable turning ability after the edge knife is worn. At the same time, supplemented by screw machines, advanced geological radars, advanced water drilling, advanced pre – treatment systems, etc., it provides solid technical support for the TBM in small – radius curves, large – slope uphill sections and long – distance tunneling, and realizes smooth tunneling in complex geological environments like “water tofu”.

It is reported that the three shield lines of the Section 7 Project need to pass through dense building groups, with risks such as settlement and cracking of house walls, which is a risk at the level of Guangzhou Metro Group and has great construction difficulties. Relying on the rich construction experience of the China Construction Fourth Engineering Division Project Department, measures such as combining manual monitoring and automatic monitoring were adopted, the 24 – hour shift system was implemented, and grouting reinforcement was carried out in advance for houses and karst caves in sections with poor geology, which effectively ensured the safety and stability of buildings in the construction section, successfully overcame this “group – level risk”, and was also praised by Guangzhou Metro Group Co., Ltd.

At present, the construction of the Fangbai Intercity Project is progressing steadily. Guangzhou Sunward said that it will continue to increase R & D investment, optimize equipment performance, and continuously improve service levels. The company firmly believes that with the strong leadership of the owner unit and the joint efforts of all parties, the Fangcun – Baiyun Airport Intercity Railway Project will surely complete the construction task with high quality and inject new vitality into the transportation development of the Greater Bay Area!