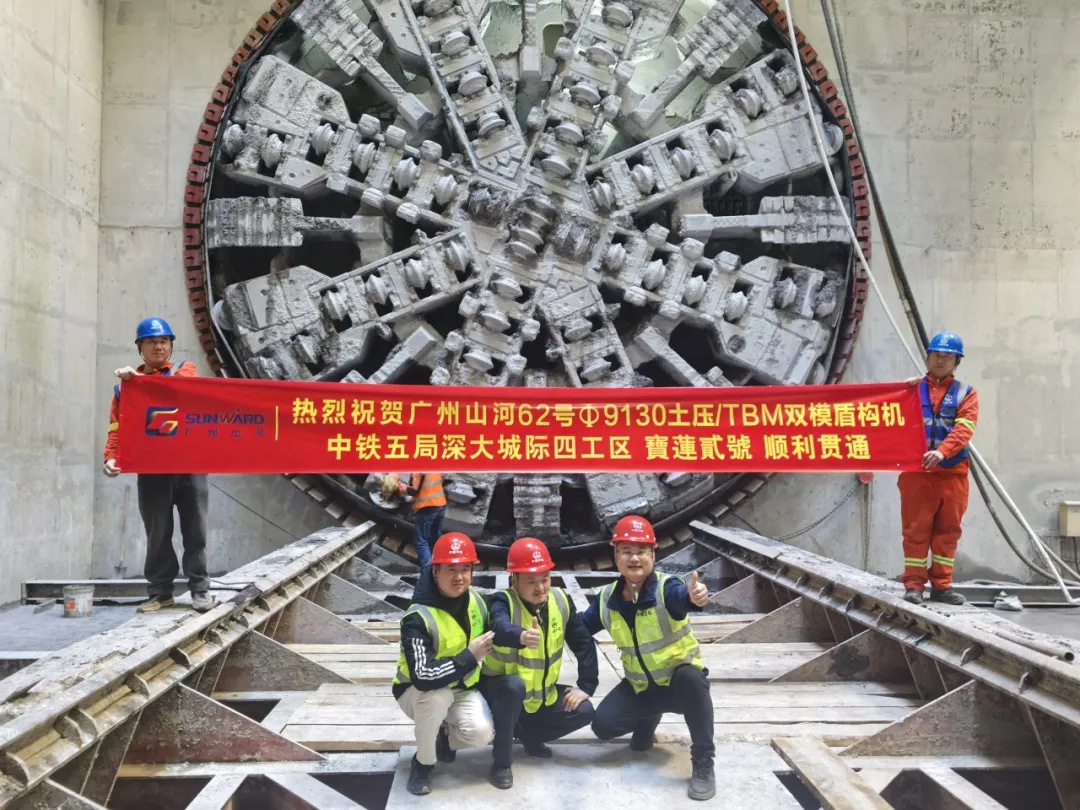

Recently, two large – diameter intelligent earth – pressure TBM dual – mode shield machines developed by Guangzhou Sunward have successfully completed the tunneling task, marking the successful double – line breakthrough of the interval from Bainikeng Station to Baida No.1 Shaft of the Shenzhen – Huizhou Intercity Railway. The smooth completion of this tunneling task not only demonstrates Guangzhou Sunward’s outstanding strength in the research and development and manufacturing of shield machines, but also reflects the superb technical level and efficient execution of the construction team of China Railway Fifth Bureau.

It is reported that since the project started, the project has continuously set new construction progress records. The highest daily tunneling footage reached 20 meters, and the highest monthly tunneling footage was as high as 502 meters. After 15 months of day – and – night struggle, the double lines of this interval were successfully connected, nearly 16 months ahead of the original planned construction period.

01 Project Overview

The Shenzhen – Huizhou Intercity Railway is an important part of the intercity railway network in the Guangdong – Hong Kong – Macao Greater Bay Area. It starts at Shenzhen Bao’an Airport and ends at Daya Bay, Huizhou, with a total length of 88.8 kilometers. It is a key project for Shenzhen to implement the eastward development strategy and open up eastern transportation, and is of great significance for promoting transportation interconnection in the Bay Area and the integration of the Shenzhen – Dongguan – Huizhou metropolitan area.

02 Project Introduction

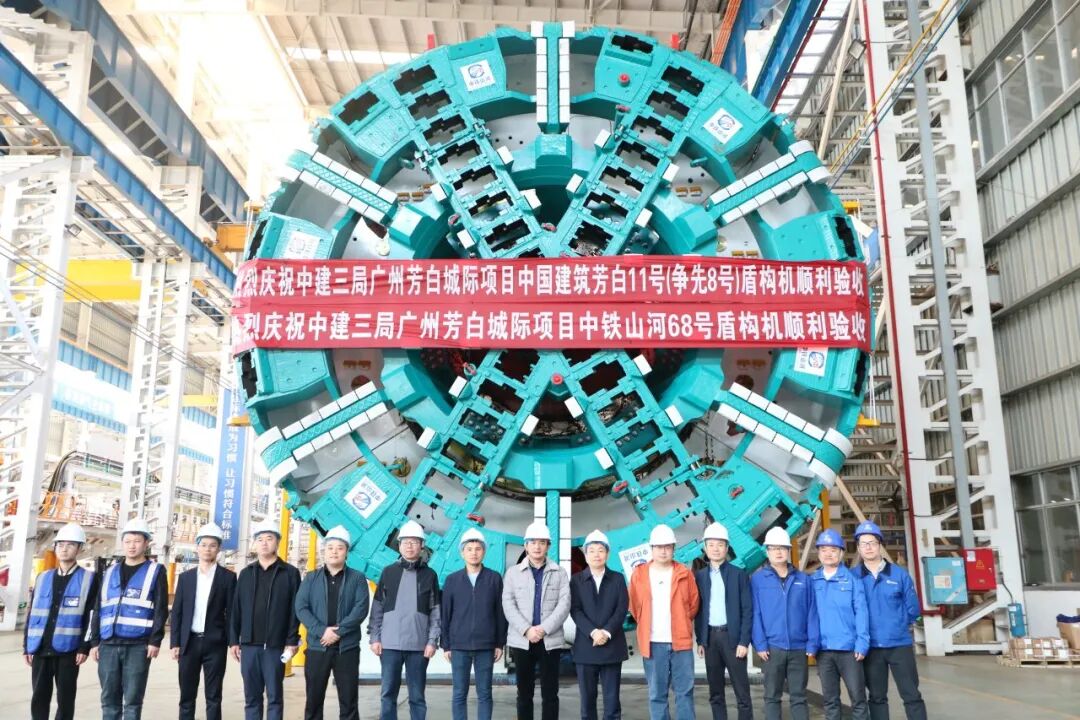

The interval from Bainikeng Station to Baida No.1 Shaft of the Shenzhen – Huizhou Intercity Railway, constructed by China Railway Fifth Bureau, has a total length of 6,165.4 meters and is constructed with two dual – mode shield machines with a diameter of 9,130 mm.

Project Difficulties

The project passes under five risk sources in turn: Bainikeng Building Group, Pingyan Railway, Paipang Interchange, Hangzhou – Shenzhen Railway, and Yantian Tunnel, and is received at Baida 1# working shaft. The interval has a long length passing under risk sources, complex stratum, many geological mutations, and high tool wear rate; it is difficult to model tool change in pressurized chambers, and the tunneling efficiency is low; the self – stability of the arch roof is poor. To solve these problems, at the initial stage of shield machine design, the R & D team of Guangzhou Sunward conducted in – depth research and customized the design of the shield machine. At the same time, the shield machine is equipped with a number of intelligent management and monitoring systems to fully ensure the safety, reliability and efficiency of tunnel construction.

During the construction process, the after – sales service team of Guangzhou Sunward closely cooperated with China Railway Fifth Bureau to escort the equipment. They continuously optimized the equipment performance and solved various technical problems in construction in a timely manner with professional technology. With high – quality equipment and excellent after – sales service, Guangzhou Sunward has won high praise and full recognition from the project department of China Railway Fifth Bureau.

03 Project Review

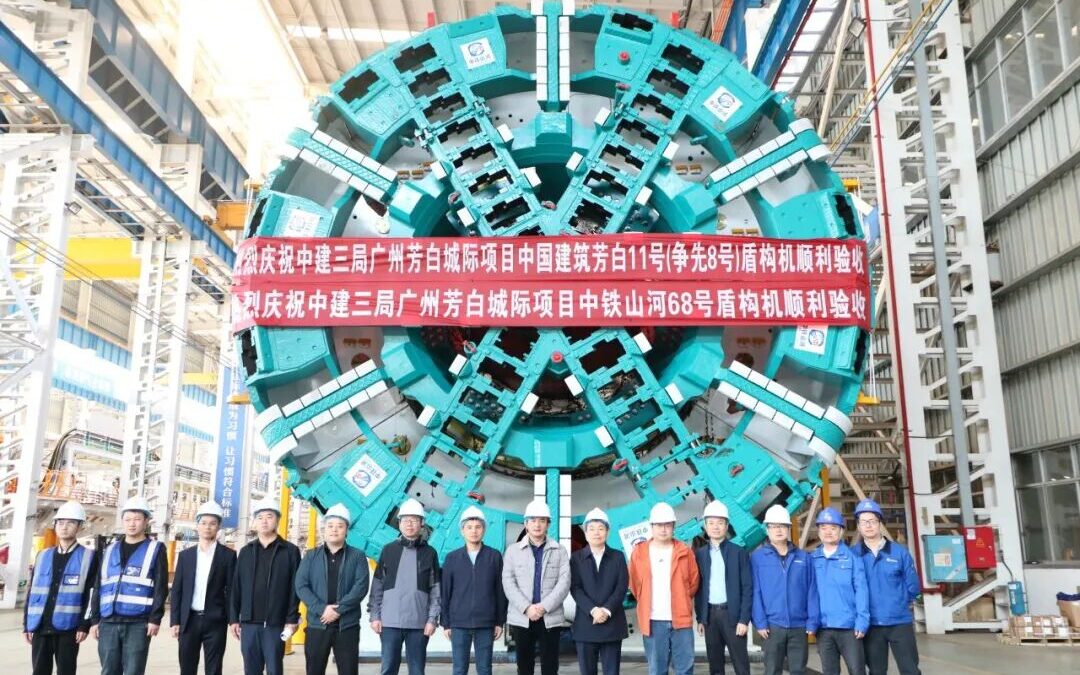

Factory Acceptance in July 2023

Shield Machine Launch in August 2023

Double – Line Breakthrough in January 2025

Since its establishment, Guangzhou Sunward has taken it as its mission to provide high – end underground engineering equipment and high – quality services. Up to now, it has provided equipment and services to many large state – owned enterprises and won their high praise. In the future, Guangzhou Sunward will continue to increase scientific research investment, optimize equipment performance, and continuously improve service levels to make greater contributions to promoting the development of underground space.